Product Line

Position sensors & object recognition

Position detection from simple proximity switches, encoders and optical systems to individual evaluation systems: ifm offers an extensive range of position sensors.

Fluid sensors & diagnostic systems

Monitoring of fluids and vibrations. ifm offers a wide range of electronic sensors, from monitoring of liquids, gases, granulates and viscous media to vibration analysis of machines and installations.

Bus system AS-Interface

Easy communication - up to the highest level AS-Interface the decentralised and intelligent system for the connection of sensors and actuators to the control level.

Control Systems

Control systems for mobile applications - ecomatmobile

A complete system, designed to perform in the extreme conditions of mobile and tough

applications.

Identification systems

Identification and coding for industrial control

RFID and Data Matrix Code (2D) provide reliable tracking and coding of manufacturing parts.

Products are simple to use and offer an ideal price-to-performance ratio.

Accessories

Quick mounting and connecting of sensors

Sensible accessories allow you to save time and cost and to increase operational reliability.

From mounting adapters to connectors, from process adapters to thermowells - we offer

everything you need for your application.

Automation Sensors

Compact Vibration Monitor With Transmitter & Switching Output

Permanent machine protection made easy

- Permanent vibration monitoring according to ISO 10816.

- Switching output with adjustable switch point and response delay.

- Transmitter signal 4...20 mA for direct display at the control desk.

- LED display on the unit.

- Easy adjustment via two setting rings allowing optimum read-out.

The electronic VK type vibration monitor monitors online the overall vibration condition of machines and equipment according to DIN ISO 10816. The sensor measures the rms vibration velocity on a non-rotating component surface. When an adjustable limit value is exceeded the unit sets to alarm via a switching contact. In addition the characteristic value is provided as current signal (4...20 mA) for connection to the process control system.

Easy operating conceptThe easy set-up via 2 radial setting rings allows quick setting of the switch point and response delay. The protective cap, which can be obtained as an accessory, ensures protection against tampering

Vibration monitor VKSetting of the switch point and response delay via setting rings directly on the unit. Monitoring of the overall vibration condition of machines and equipment according to ISO 10816.

Compact Fusion of electronic pressure sensor and analogue display

Good readability and electronic signal processing mean reliable operation.

- Optimum readability by electronic pointer display.

- Rotatable display with LED bargraph for switch point indication.

- Output functions programmable via LED display and optical touch fields.

- Hygienic flush design and high total accuracy (0.2 %).

- Aseptoflex Vario – new G 1 process connection with 4 sealing options.

In the process industry mechanical contact manometers are often used because of their highly

visible display. The electronic "contact manometer" of the series PG combines the high

visibility of a manometer display with the advantages of an electronic pressure sensor.

Compared to mechanical contact manometers it features more varied options.

The high-quality sensor family PI is used as a basic unit completed by an analogue display

with high readability. Especially the programmable switching output and analogue output

(scalable), the high overload protection as well as the integrated temperature compensation

are worth mentioning. The manometer has a resolution of 0.25 %. When disconnected, the pointer

is not visible

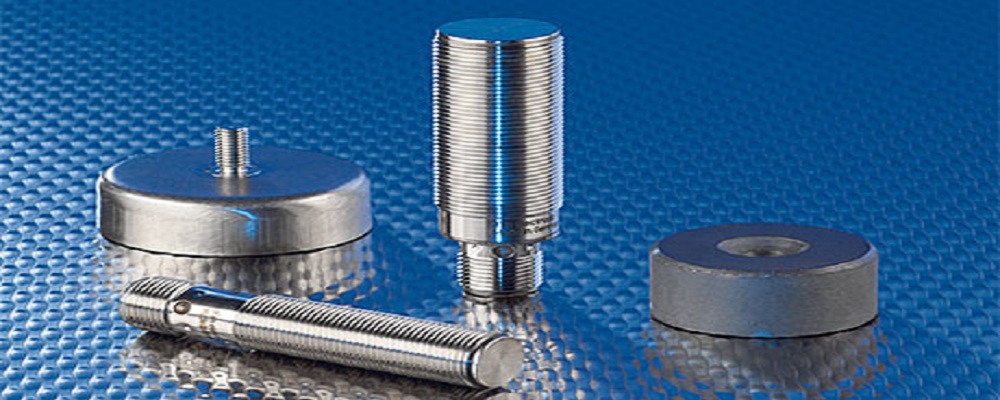

Full metal housing inductive sensors for heavy duty

Tough: extremely resistant to mechanical wear

- Ideal for metalworking applications.

- Non-stick coating against weld spatter.

- Mechanically resistant to impacts on the sensing face.

- Vibration and shock resistant.

- Lasered type label: permanently legible.

The threaded body and the sensing face of the housing are made of high-grade stainless steel.

Use in welding applicationsThe non-stick coating allows weld spatter to roll off the sensor. The high temperature range of up to 85 °C means it can handle critical applications.

Application testsA series of tests qualified the sensors for tough applications:

- vibration test

- shock test

- impact test

- wire brush test

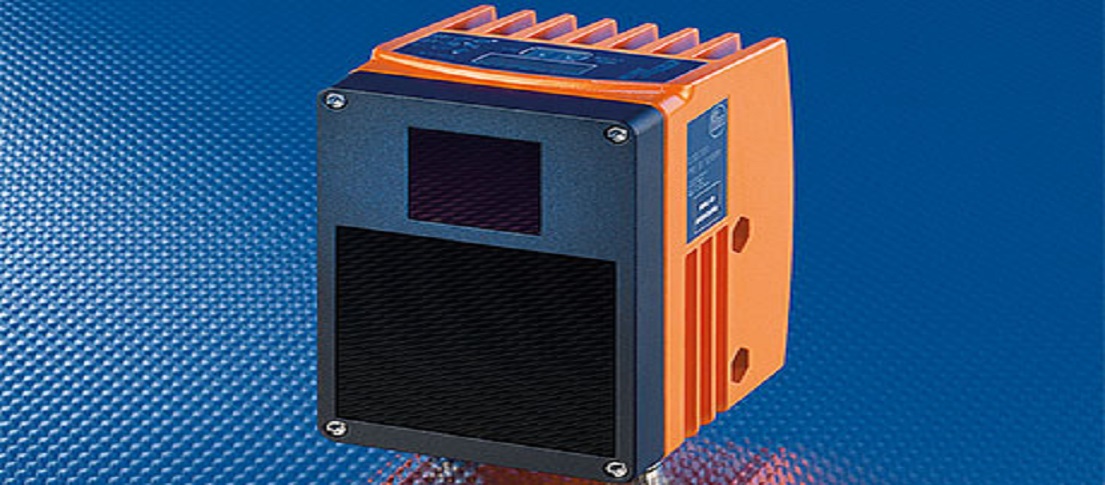

A quantum leap in optoelectronics: sensing in 3D

Visual assessment of distance, level or volume.

- Detection of scenes and objects in three dimensions at a glance.

- Operating principle: time-of-flight measurement based on pmd technology.

- Illumination, time-of-flight measurement and evaluation in one housing.

- 3,072 distance values per measurement for the detailed assessment of the application.

- 4...20 mA / 0...10 V analogue output or 2 switching outputs for indication of the results.

efector pmd 3d is the first industrial 3D sensor that can detect objects in three dimensions at a glance. The time-of-flight measurement in three dimensions enables the assessment of different applications, for example the detection of volume, distance or level. Special feature: the time-of-flight measurement and evaluation are integrated on one chip. The sensor chip has 64 x 48 pixels. Each pixel of this chip matrix evaluates its distance to the object. This results in 3,072 distance values at the same time. The image of the object on the chip matrix and the respective distance values correspond to a 3D image. These values enable the detailed assessment of the object's or scene's characteristics

Image sensor "efector pmd 3dThe non-stick coating allows weld spatter to roll off the sensor. The high temperature range of up to 85 °C means it can handle critical applications.

Application testsA series of tests qualified the sensors for tough applications:

- vibration test

- shock test

- impact test

- wire brush test

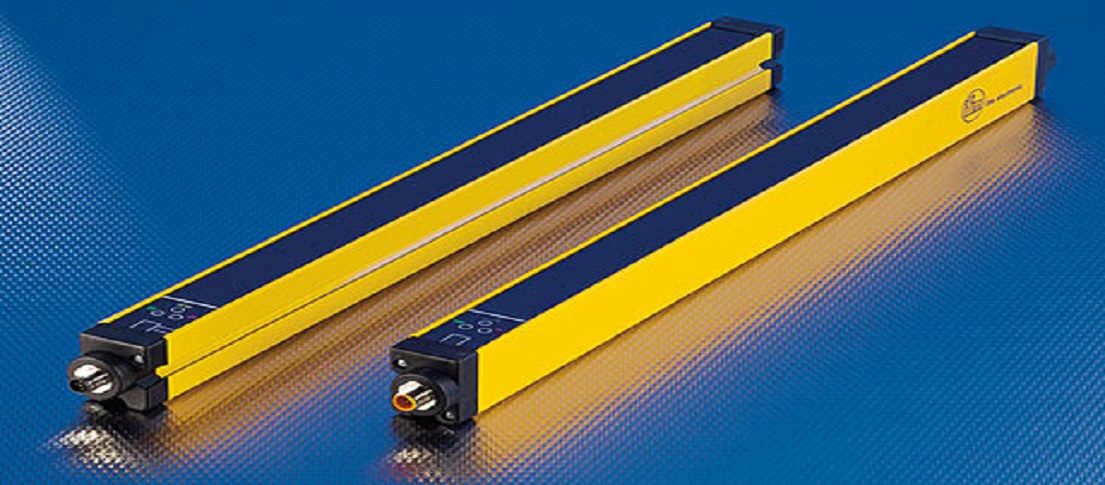

Safety light curtains in lean design with high ranges

New light curtain takes centre stage.

- Type 2 and type 4 safety light curtains to IEC 61496.

- Now with SIL to IEC 61508 and PL to ISO 13849.

- Can be installed without dead band. Mounting accessories supplied with the units.

- Ranges selectable on the unit: 0...4 m or 3...12 m.

- Easy to connect via the tried and tested M12 connector (5- or 8-pin).

The safety light curtains and light grids have been developed in accordance with the current standards and certified by TÜV Süd. They meet the requirements type 2 / SIL2 or type 4 / SIL3. So you are on the safe side if you need primary guarding or access prevention.

VariantsThese light curtains are available for protected area heights of 160 mm to 1510 mm in intervals of 150 mm. The resolution (detection capacity) is selectable between 30, 40, 50 or 90 mm. The light grids are available in 2-, 3- or 4-beam version. They all have one thing in common: the very small housing dimensions of only 28 x 30 mm.

Easy installationVia the T-slot over the whole length on the back the units are easy to mount. Angle brackets are supplied with each unit and do not have to be ordered separately. The units can be installed vertically or horizontally and without dead band on one side.

Easy wiringThe units are configured via the pin connection of the 5- or 8-pin M12 connector. To do so, you need no PC or software. Functions such as EDM (External Device Monitoring), restart or external muting (safety relay G2001S) can be implemented.

Applications:Access limitations and primary guarding, robot cells, pick-and-place machines, production lines in industrial automation.

Full-metal pressure sensors for hygienic applications

Now with enhanced sealing system.

- High overall accuracy (0.2 %) and electronic temperature compensation.

- Programmable analogue and switching output.

- Hygienic, flush design with high-purity ceramic measuring cell.

- Aseptoflex Vario – new G 1 process connection with 4 sealing options.

- High temperature resistance, therefore suitable for SIP and CIP processes.

The new pressure sensors of the PI27 series have a high-grade stainless steel housing. The

housing design is, in particular, distinguished by its resistance to cleaning agents used in

the food and pharma industries whose effectiveness is constantly increasing. Lasered, captive

type labels are natural for these sensors.

The excellent features and characteristics of the former PI sensors are also provided by the

new series: high protection IP 69K, hygienic design, high temperature resistance, high-purity

ceramic measuring cell, high-quality materials (wetted parts) and last but not least intuitive

operation.

Output function PNP/NPN programmable + programmable output function